Blog

Prerequisite to FSMA is Sanitation

This blog post is a 19 minute read

The Food Safety Modernization Act (FSMA) focuses on prevention—and sanitation efforts are a key part of your success in complying with FSMA regulations. In this post, we will take a detailed look at why sanitation efforts are central to compliance and how these new standards fit with the food safety act.

One of the “hazards” of using acronyms is there can be a risk of confusion when new ones are introduced, especially if new ones are similar to ones previously used.

HACCP stands for Hazard Analysis and Critical Control Points. It’s an internationally recognized standard method of assessing food safety-related risks.

HARPC is Hazard Analysis and Risk-Based Preventative Controls. It’s a newer standard that is mandated by the FSMA regulations for all food establishments unless an establishment is specifically exempted.

It is incorrect to think of HARPC as a replacement for HACCP as they are both currently in effect and each has specific applications. Instead, think of HARPC as providing additional guidance to develop preventative control plans.

About HACCP

HACCP covers three big food safety hazards: biological hazards, physical hazards, and chemical hazards. The priority is to tackle these hazards in the following order: first, prevent the hazard; next, eliminate the hazard, and finally, reduce the hazard to a safe level.

HACCP covers three big food safety hazards: biological hazards, physical hazards, and chemical hazards. The priority is to tackle these hazards in the following order: first, prevent the hazard; next, eliminate the hazard, and finally, reduce the hazard to a safe level.

There are seven principles of HACCP, which are instructive to illustrate how they work together and build on one another to lead to safe food handling.

- Conduct a hazard analysis– This principle examines all of the steps and actions involved and a HACCP team will identify where it’s likely for significant hazards to occur in the process.

- Identify the critical control points– A “critical control point” is exactly what it sounds like: a point in the process where the application of a control measure will eliminate or reduce a food safety hazard.

- Establish critical limits– A “critical limit” is a maximum or minimum level for a parameter that affects food safety. Examples are time and temperature, or pH levels, that are based on scientific or regulatory standards. These are measurable limits and quantifiable numbers.

- Monitor critical control points– Monitoring the critical limits at the identified critical control points is a structured process: there is an established process for taking measurements that describes who, what, when, and how each parameter is recorded.

- Establish corrective action– When a number outside of a critical limit is identified and recorded, corrective action needs to be taken to make sure that potentially unsafe food doesn’t reach the food chain.

- Verification– These are processes outside of critical control point monitoring that establish the system is working correctly—and they need to be independent. Audits, reviews, and equipment calibration are all examples of verification systems.

- Recordkeeping– Recordkeeping is a critically important step, as it provides evidence that processes are being correctly followed. There are specific requirements for HACCP recordkeeping that must be followed.

Each principle above logically leads to the next, creating a process by which food safety is the paramount concern.

You will also see references to the “12 steps of HACCP.” This includes five steps that happen beforethe seven principles listed above. They include assembling a HACCP team, describing the product, defining its intended use, developing a flow diagram, and physically verifying the flow diagram at the plant.

HARPC – Adds Additional Concerns

As noted above, HACCP covers three food hazards: biological, physical, and chemical hazards that can impact food safety.

HARPC includes additional concern areas. These include hazards such as radiation, naturally occurring toxins, parasites and pesticides, allergens, drug residues, food/color additives that have not been approved by regulatory authorities, and decomposed material.

Because part of the FSMA regulations grew out of concerns that our food system was potentially vulnerable to bioterrorism, HARPC includes assessing for risks of intentional introduction of hazards, such as terrorism.

The seven steps of HARPC mirror some of the seven principles of HACCP, but do include some key differences. “Assess the hazards” is similar to “conduct a hazard analysis” and verification and recordkeeping requirements are likewise quite similar. However, HARPC’s second step is “institute preventative controls,” which includes items like sanitation procedures, staff hygiene training, and verifying suppliers, that are very different from HACCP.

One of the “hazards” of using acronyms is there can be a risk of confusion when new ones are introduced, especially if new ones are similar to ones previously used.

HACCP stands for Hazard Analysis and Critical Control Points. It’s an internationally recognized standard method of assessing food safety-related risks.

HARPC is Hazard Analysis and Risk-Based Preventative Controls. It’s a newer standard that is mandated by the FSMA regulations for all food establishments unless an establishment is specifically exempted.

It is incorrect to think of HARPC as a replacement for HACCP as they are both currently in effect and each has specific applications. Instead, think of HARPC as providing additional guidance to develop preventative control plans.

About HACCP

HACCP covers three big food safety hazards: biological hazards, physical hazards, and chemical hazards. The priority is to tackle these hazards in the following order: first, prevent the hazard; next, eliminate the hazard, and finally, reduce the hazard to a safe level.

HACCP covers three big food safety hazards: biological hazards, physical hazards, and chemical hazards. The priority is to tackle these hazards in the following order: first, prevent the hazard; next, eliminate the hazard, and finally, reduce the hazard to a safe level.

There are seven principles of HACCP, which are instructive to illustrate how they work together and build on one another to lead to safe food handling.

- Conduct a hazard analysis– This principle examines all of the steps and actions involved and a HACCP team will identify where it’s likely for significant hazards to occur in the process.

- Identify the critical control points– A “critical control point” is exactly what it sounds like: a point in the process where the application of a control measure will eliminate or reduce a food safety hazard.

- Establish critical limits– A “critical limit” is a maximum or minimum level for a parameter that affects food safety. Examples are time and temperature, or pH levels, that are based on scientific or regulatory standards. These are measurable limits and quantifiable numbers.

- Monitor critical control points– Monitoring the critical limits at the identified critical control points is a structured process: there is an established process for taking measurements that describes who, what, when, and how each parameter is recorded.

- Establish corrective action– When a number outside of a critical limit is identified and recorded, corrective action needs to be taken to make sure that potentially unsafe food doesn’t reach the food chain.

- Verification– These are processes outside of critical control point monitoring that establish the system is working correctly—and they need to be independent. Audits, reviews, and equipment calibration are all examples of verification systems.

- Recordkeeping– Recordkeeping is a critically important step, as it provides evidence that processes are being correctly followed. There are specific requirements for HACCP recordkeeping that must be followed.

Each principle above logically leads to the next, creating a process by which food safety is the paramount concern.

You will also see references to the “12 steps of HACCP.” This includes five steps that happen beforethe seven principles listed above. They include assembling a HACCP team, describing the product, defining its intended use, developing a flow diagram, and physically verifying the flow diagram at the plant.

HARPC – Adds Additional Concerns

As noted above, HACCP covers three food hazards: biological, physical, and chemical hazards that can impact food safety.

HARPC includes additional concern areas. These include hazards such as radiation, naturally occurring toxins, parasites and pesticides, allergens, drug residues, food/color additives that have not been approved by regulatory authorities, and decomposed material.

Because part of the FSMA regulations grew out of concerns that our food system was potentially vulnerable to bioterrorism, HARPC includes assessing for risks of intentional introduction of hazards, such as terrorism.

The seven steps of HARPC mirror some of the seven principles of HACCP, but do include some key differences. “Assess the hazards” is similar to “conduct a hazard analysis” and verification and recordkeeping requirements are likewise quite similar. However, HARPC’s second step is “institute preventative controls,” which includes items like sanitation procedures, staff hygiene training, and verifying suppliers, that are very different from HACCP.

The Food Safety Modernization Act

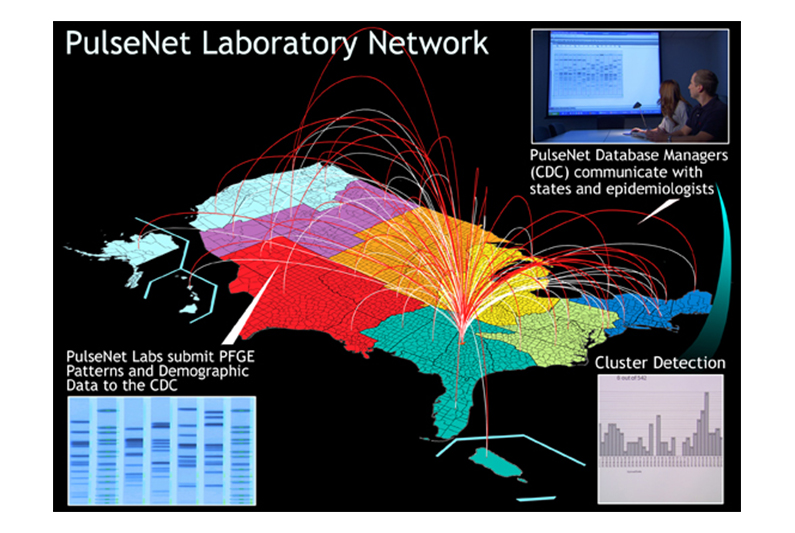

Microbes causing food-related illnesses have a DNA profile that allows trace back to the raw material and to the manufacturing plant doing the packaging (click above to view full version).

We’ve posted before about FSMA, along with a bit of history of food and drug safety and regulation in the US. The biggest change that FSMA regulations represent is the shift in emphasis from responding to foodborne illness outbreaks to preventing them from happening in the first place.

Preventing outbreaks of foodborne illnesses is a major public health concern and for companies that experience a recall, it is a brand reputation issue.

Nearly 48 million Americans—about one in six—get sick every year from foodborne illnesses. Alarmingly, nearly 128,000 are hospitalized and 3,000 people die each year from foodborne diseases according to the Centers for Disease Control and Prevention.

It is in everyone’s interest to identify and remediate problems before food products make their way to the consumer. With this shift from reactive to preventative, risk detection and sanitation are now front and center to ensuring FSMA compliance.

HACCP and HARPC – Defined

[wpdatatable id=57]

Source: https://www.foodsafetymagazine.com/enewsletter/haccp-vs-harpc-a-comparison/

One of the “hazards” of using acronyms is there can be a risk of confusion when new ones are introduced, especially if new ones are similar to ones previously used.

HACCP stands for Hazard Analysis and Critical Control Points. It’s an internationally recognized standard method of assessing food safety-related risks.

HARPC is Hazard Analysis and Risk-Based Preventative Controls. It’s a newer standard that is mandated by the FSMA regulations for all food establishments unless an establishment is specifically exempted.

It is incorrect to think of HARPC as a replacement for HACCP as they are both currently in effect and each has specific applications. Instead, think of HARPC as providing additional guidance to develop preventative control plans.

About HACCP

HACCP covers three big food safety hazards: biological hazards, physical hazards, and chemical hazards. The priority is to tackle these hazards in the following order: first, prevent the hazard; next, eliminate the hazard, and finally, reduce the hazard to a safe level.

HACCP covers three big food safety hazards: biological hazards, physical hazards, and chemical hazards. The priority is to tackle these hazards in the following order: first, prevent the hazard; next, eliminate the hazard, and finally, reduce the hazard to a safe level.

There are seven principles of HACCP, which are instructive to illustrate how they work together and build on one another to lead to safe food handling.

- Conduct a hazard analysis– This principle examines all of the steps and actions involved and a HACCP team will identify where it’s likely for significant hazards to occur in the process.

- Identify the critical control points– A “critical control point” is exactly what it sounds like: a point in the process where the application of a control measure will eliminate or reduce a food safety hazard.

- Establish critical limits– A “critical limit” is a maximum or minimum level for a parameter that affects food safety. Examples are time and temperature, or pH levels, that are based on scientific or regulatory standards. These are measurable limits and quantifiable numbers.

- Monitor critical control points– Monitoring the critical limits at the identified critical control points is a structured process: there is an established process for taking measurements that describes who, what, when, and how each parameter is recorded.

- Establish corrective action– When a number outside of a critical limit is identified and recorded, corrective action needs to be taken to make sure that potentially unsafe food doesn’t reach the food chain.

- Verification– These are processes outside of critical control point monitoring that establish the system is working correctly—and they need to be independent. Audits, reviews, and equipment calibration are all examples of verification systems.

- Recordkeeping– Recordkeeping is a critically important step, as it provides evidence that processes are being correctly followed. There are specific requirements for HACCP recordkeeping that must be followed.

Each principle above logically leads to the next, creating a process by which food safety is the paramount concern.

You will also see references to the “12 steps of HACCP.” This includes five steps that happen beforethe seven principles listed above. They include assembling a HACCP team, describing the product, defining its intended use, developing a flow diagram, and physically verifying the flow diagram at the plant.

HARPC – Adds Additional Concerns

As noted above, HACCP covers three food hazards: biological, physical, and chemical hazards that can impact food safety.

HARPC includes additional concern areas. These include hazards such as radiation, naturally occurring toxins, parasites and pesticides, allergens, drug residues, food/color additives that have not been approved by regulatory authorities, and decomposed material.

Because part of the FSMA regulations grew out of concerns that our food system was potentially vulnerable to bioterrorism, HARPC includes assessing for risks of intentional introduction of hazards, such as terrorism.

The seven steps of HARPC mirror some of the seven principles of HACCP, but do include some key differences. “Assess the hazards” is similar to “conduct a hazard analysis” and verification and recordkeeping requirements are likewise quite similar. However, HARPC’s second step is “institute preventative controls,” which includes items like sanitation procedures, staff hygiene training, and verifying suppliers, that are very different from HACCP.

Sanitation and FSMA Compliance

Technician using water pressure in factory

Sanitation is a cornerstone of FSMA compliance, and having solid sanitation protocols in place is critically important. The shift to prevention in the food safety act makes sanitation testing critically important to compliance with FSMA.

“Preventative controls” is the term used by FDA to describe the steps to be taken by plants handling human food and includes all companies that “manufacture, process, pack, or hold human food for consumption in the United States.” If and when a hazard assessment (step 1 of HARPC) turns up a hazard that requires a preventative control (step 2 of HARPC), a facility must have a written plan to mitigate the hazard—and the plan must include the processes and procedures that will correct the problem.

Sanitation is a key part of these preventative controls. A written plan for sanitation controls will cover monitoring, corrective actions, and the standards of recordkeeping and verification that are included in both HACCP and HARPC.

Monitoring will include frequent testing of surfaces and hygiene verification. ATP (adenosine triphosphate) testing is used to detect the presence of microorganisms on surfaces by using a luminometer. Adenosine triphosphate is a molecule found in cells and luminometers read light produced by a reaction of ATP to an enzyme, showing the level of microorganisms present on a surface.

Learn More About Sanitation Solutions for FSMA Compliance

novaLUM II-X ATP system and Charm AllerGiene Swab

Charm’s ATP testing solutions are designed to be easy to use and provide fast results—and include allergen tests such as AllerGiene to address HARPC allergen concerns. Used in conjunction with the novaLUM II-X ATP Detection System, which is a palm-sized luminometer, detection of sanitation problems is an easy process, allowing your facility to remediate quickly.

Sanitation testing is an ongoing, daily undertaking. ATP testing produces fast results, while microbial testing establishes if a food environment remains in control.

Contact us today to learn more about how Charm Sciences sanitation monitoring can help you meet the requirements of the FSMA.

About Charm Sciences

Established in 1978 in Greater Boston, Charm Sciences helps protect consumers, manufacturers, and global brands from a variety of issues through the development of food safety, water quality, and environmental diagnostics tests and equipment. Selling directly and through its network of distributors, Charm’s products serve the dairy, feed and grain, food and beverage, water, healthcare, environmental, and industrial markets in more than 100 countries around the globe. https://www.charm.com