Blog

ATP Testing Overview

ATP testing is a quick and reliable method for verifying cleaning techniques and safeguarding the microbial quality of your facility and products. By following a comprehensive ATP testing guide, you can effectively assess cleaning techniques and identify areas of microbial risk.

Understanding ATP

Adenosine triphosphate (ATP) is a molecule that carries energy. It is the main source of energy for a cell and is found in all living things, including things that were once living, like bacteria, mold, and human skin. You’ll find intracellular ATP within living biological cells and extracellular ATP outside a cell after the organism has died or experienced stress.

What Is ATP Testing?

Industries such as hospitality, food and beverage processing, and healthcare use rapid ATP tests to assess surface cleanliness quickly.

Most microbial cells and foods contain some level of naturally occurring ATP. ATP swabs use luciferin/luciferase enzyme, like those in a firefly, to detect residual ATP as an indicator of surface cleanliness. Light detectors, called luminometers, are used to detect ATP in seconds.

What Industries Need ATP Testing?

Charm Sciences’ diagnostics portfolio includes luminometers and ATP swabs to protect the brand and reputation of industries such as:

- Hospitality: Hotel managers trust our PocketSwab Plus ATP test to verify cleaning of high-touch surfaces like door knobs, handles, remotes, and sinks.

- Dairy Processing: Charm’s ATP swab tests improve shelf life of products and detect areas that need cleaning to protect the reputation and brand integrity of companies selling milk and other dairy products.

- Feed & Grain Processing: We’ve partnered with farmers to create equipment and test kits tailored to their specific needs. Charm food safety tests allow auditors and regulators to test processing facilities and shipping containers for proper hygiene.

- Food & Beverage Processing: Charm designs ATP swab tests to help food manufacturers meet various regulations, food processing authority standards, and sanitation standards.

- Water: Charm’s ATP monitoring system plays a crucial role in testing water quality to improve water management, hygiene, and sanitation practices in food, cosmetic, and pharmaceutical applications.

ATP Testing Best Practices

Understanding how ATP technology will work within a larger program is vital when utilizing an ATP testing device.

Abiding by ATP testing best practices ensure optimal results:

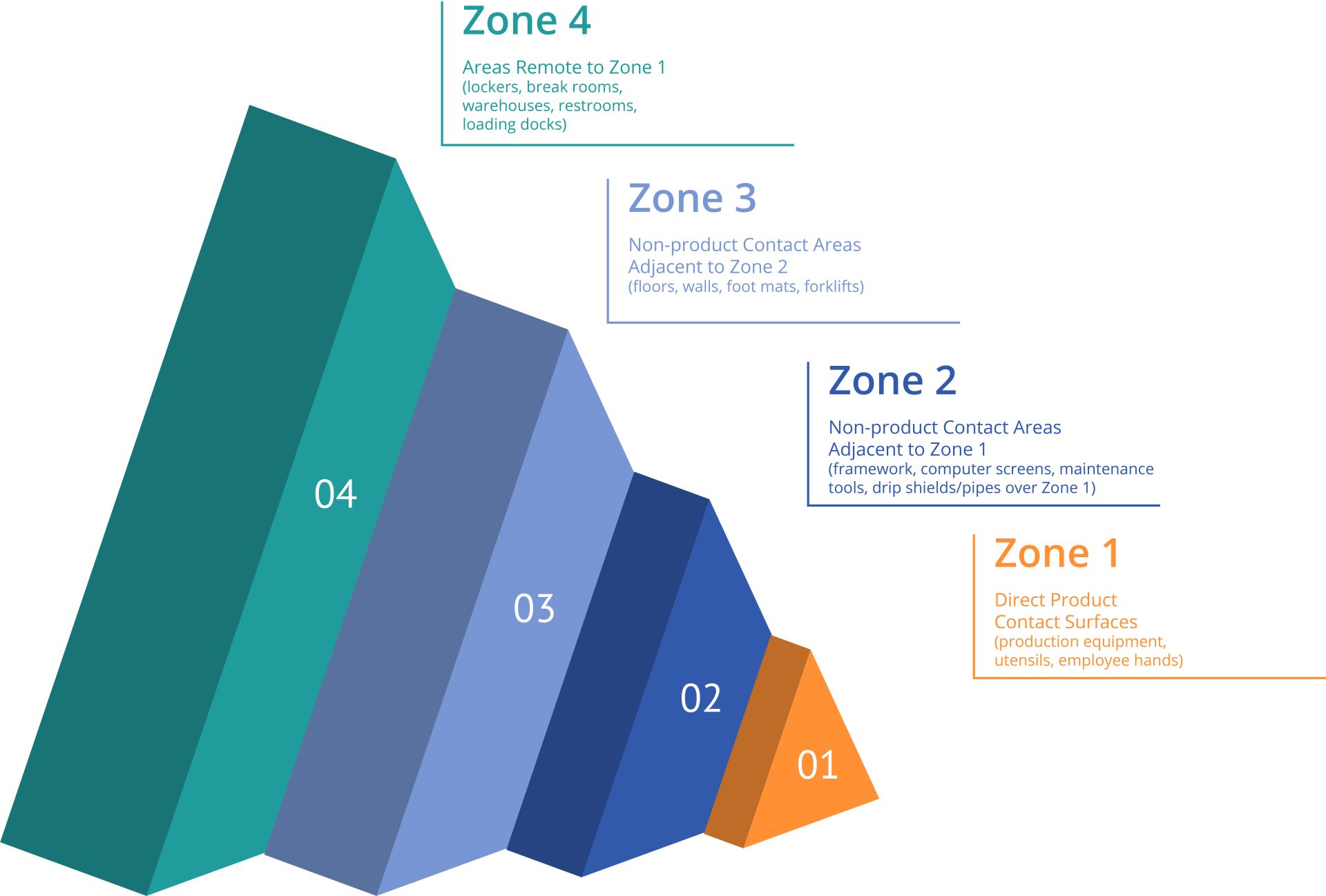

- Start by mapping your entire facility into zones, where 1 is the most critical, surrounded by zones 2, 3, and 4.

- Collaborate with your team to identify the most relevant test points while mapping the complete environment. For example, map entry points and traffic flow patterns.

- Determine the testing scheme best suited to your test points’ unique purposes.

- When evaluating how important given test points are, consider how challenging the surface is to clean.

- Regularly monitor Zone 1 test points, especially before employee use, as these areas pose the highest risk.

- Monitor lower-risk areas often enough to ensure sanitation efforts are sufficient to secure your facility’s inner zone safety.

- Evaluate ATP results and trends over time to increase the effectiveness of your cleaning process and lower your overall risk.

The ATP Testing Process

The ATP test works by swabbing a surface to pick up any ATP on the swab. The swab is then activated with the luciferase enzyme contained in the test vial and inserted into a luminometer. Any ATP present on the swab will react with the enzyme and begin to produce light. A luminometer then measures the amount of light produced and reports it as relative light units (RLUs). By designating a specific RLU threshold, you can easily measure whether a surface meets your sanitation criteria and whether it is ready for use, needs recleaning, or needs to be studied for route cause of failure.

The testing process for receiving an ATP value reading is simple. You will need a designated ATP testing swab and a compatible luminometer. Keeping these materials readily available at all relevant testing sites will enhance convenience for your staff.

- Clean the surface: Before you test for ATP, visually clean the surface you plan to verify. ATP tests can tell you whether the visually clean surface is biologically clean and help you understand if your cleaning methods are effective.

- Swab the area: Use your ATP testing swab to gather a sample from your cleaned surface. Apply pressure to the swab as you run it along the clean surface and rotate to collect sample material along all sides.

- Insert swab into the luminometer: Follow manufacturer instructions for placing the swab in the tube. Some tubes may already have a reactant inside. Others may require you to snap the tube to release the detection agent. Typically, you will need to shake the tube to initiate the reaction.

- Read results with a luminometer: The luminometer is critical to your ATP testing because it will read ATP values on your testing surface. Your swab tube should fit in the luminometer and provide results in seconds.

Considerations for Testing

While the testing process is straightforward, it’s vital to understand the specific testing conditions and how to use your test results. ATP testing provides a value for cleaning verification, but there are a few additional considerations to ensure comprehensive risk mitigation in your facility.

- Measurement values: A luminometer will measure ATP by accounting for the level of bioluminescence in a sample. You’ll receive a quantitative measure in RLUs. This measure is a good indication of the presence of ATP and surface cleanliness, in turn. However, RLUs do not necessarily correlate with colony-forming units (CFUs), a unit of measure gauging unsafe levels of bacteria and fungi. For simplicity during testing, you can set a specific threshold for easy pass/fail readings.

- Setting a baseline: Many regulatory bodies define safety levels in CFUs, so you’ll need to determine a safe baseline in RLUs. Every facility and surface will have different standards for a passing and failing RLU value. Your test equipment provider may be able to provide insight based on your industry. Repeated testing over a long period can help you determine what a standard value is for a surface. Your luminometer may also provide helpful data for generating a baseline.

- Testing times: The recommendation for ATP testing is after cleaning and before sanitization, as some test kits may interact with sanitizers and deliver inaccurate results. If you choose to test after sanitizing, you will want to verify if it affects the final reading in the luminometer.

- Other testing types: You may choose to use ATP testing in addition to other testing types for a comprehensive analysis of surface safety. Microbial testing systems work well alongside ATP tests to provide more detail about what kinds of microorganisms are present. It’s also important to note that ATP measurements do not account for the presence of viruses.

- Biofilm: Microorganisms can create a sticky layer to protect themselves. Biofilms can make it harder to sanitize a surface. Your swabbing device should be capable of breaking through these biofilms to get accurate readings.

Benefits of ATP Testing

Introducing regular ATP testing at your business can offer many advantages.

Meet Regulations and Policies

Many organizations must adhere to specific regulations and standards about the cleanliness of their facilities. ATP testing becomes a valuable tool in ensuring compliance with guidelines and demonstrating a commitment to hygiene. This objective testing measure can help you create clear records that back up the efficacy of your sanitation procedures.

Increase Accuracy

An ATP test assesses the cleanliness of the surface beyond what the eye can see, making it a more accurate method for verifying cleanliness. These tests provide objective information about ATP levels so users can clearly gauge when cleaning methods are effective and if they need to modify their techniques. ATP testing can also detect food product residues that are challenging to detect with visual inspections. These residues can leave nutrients that help organisms grow and spread. Addressing these nutrients at the source can mitigate organism growth.

Improve Efficiency

You can complete an ATP test in a matter of seconds, making this method a proactive step before any critical contact and an efficient verification solution for your sanitation processes. Time constraints can limit sanitation verification when operations have tight deadlines making those longer test results retrospective, but ATP testing can eliminate this issue. With a fast swab and reading, staff members can easily and efficiently integrate testing into their cleaning routines and remediate if needed.

Avoid Outbreaks

ATP testing can be a valuable investment for your organization. With the accuracy of these tests, your staff can catch sanitation issues before they become unmanageable. The costs associated with outbreaks include medical treatment for affected individuals, diminished productivity, obligatory reporting, business losses stemming from a decline in trust, and more. Implementing ATP testing in your facility can help you catch cleanliness problems before they reach the public.

This prevention can apply to food and beverage, hospitality, cosmetics, healthcare, and other industries.

Demonstrate Commitment to Quality

With heightened concerns over sanitation, consumers and business partners want to know how brands and companies implement quality control in food production, schools, hospitals, and hotels. You can assure your customers about their safety with ATP testing. With objective validation of cleanliness, all individuals involved with your company can trust your sanitation techniques. This demonstrated commitment to quality can improve your brand identity and build trust with your customers, buyers, and suppliers. A solid reputation can lead to a more successful business in the long term.

Tips for Keeping Your Facility Clean

While integrating ATP testing into your workflow can verify cleaning processes, there are many methods you can use to ensure your facility’s sanitation stays up to standard.

Establish a Routine

Creating a defined cleaning routine ensures your staff methodically cleans every surface that needs it. Your routine can include times of day for cleaning, processes for testing post-cleaning, and testing requirements for each process. Developing these routines can also help your staff complete cleaning responsibilities more efficiently. Consider creating a master document for cleaning routines throughout the facility to reference during training. You can also create separate documents for different hygiene areas to break down the routine in each zone.

Track and Trend the Results

Review results. Require retests and passing results whenever a test site fails to meets its RLU cut-off. Track repeat failing sites and determine the cause of failure by creating Corrective and Preventative Actions (CAPA). Create vector sites around repeat failures to help improve cleaning and determine the root cause of problems.

Assess the Risks

When teaching staff members about cleaning techniques, emphasize the importance of inspecting the area before cleaning. This initial inspection is essential for identifying any risks in the area and addressing hazards before cleaning starts. Janitorial services, in particular, may face spills that pose safety risks. Another notable risk is the harsh chemical compounds in certain cleaning products. If your staff handles cleaning products, they should know the appropriate personal protective equipment (PPE) to wear, like rubber gloves.

Organize Your Facility

Keeping your cleaning supplies organized will support efficiency during cleaning processes and help staff members use the right tools and materials according to your cleaning routine. For example, if you integrate ATP testing into your routine, employees should be familiar with the location of test swabs and available luminometers for testing. Clearly label all cleaning products, materials, and tools in closets and other storage areas for easy access.

Conduct Site Inspections

Scheduling site inspections can help teams gauge their cleaning performance over time. Consider conducting these inspections once a month to assess the state of your facility. You may incorporate ATP testing into this process to verify the thoroughness of your cleaning processes. Notate poorly cleaned areas so you can modify your routine and retrain staff as needed.

Charm Sciences ATP Tests

Charm Sciences offers ATP testing kits to organizations across industries that prioritize cleanliness and safety. Our ATP tests feature the PocketSwab Plus ATP Test — a self-contained, single-service swab designed for surface sanitation verification.

These swabs are pre-moistened with a special breaking agent to address the challenges of biofilm in ATP detection. The swab also features a patented thread design for consistent results from user to user and can be used on both wet and dry surfaces. Its foam swab is better at picking up samples than other swabs. PocketSwab Plus ATP test uses a microtube to break through microbial cells and sanitizers to read ATP accurately. Once you’ve attached a swab to our luminometer, you get results in just 5 seconds.

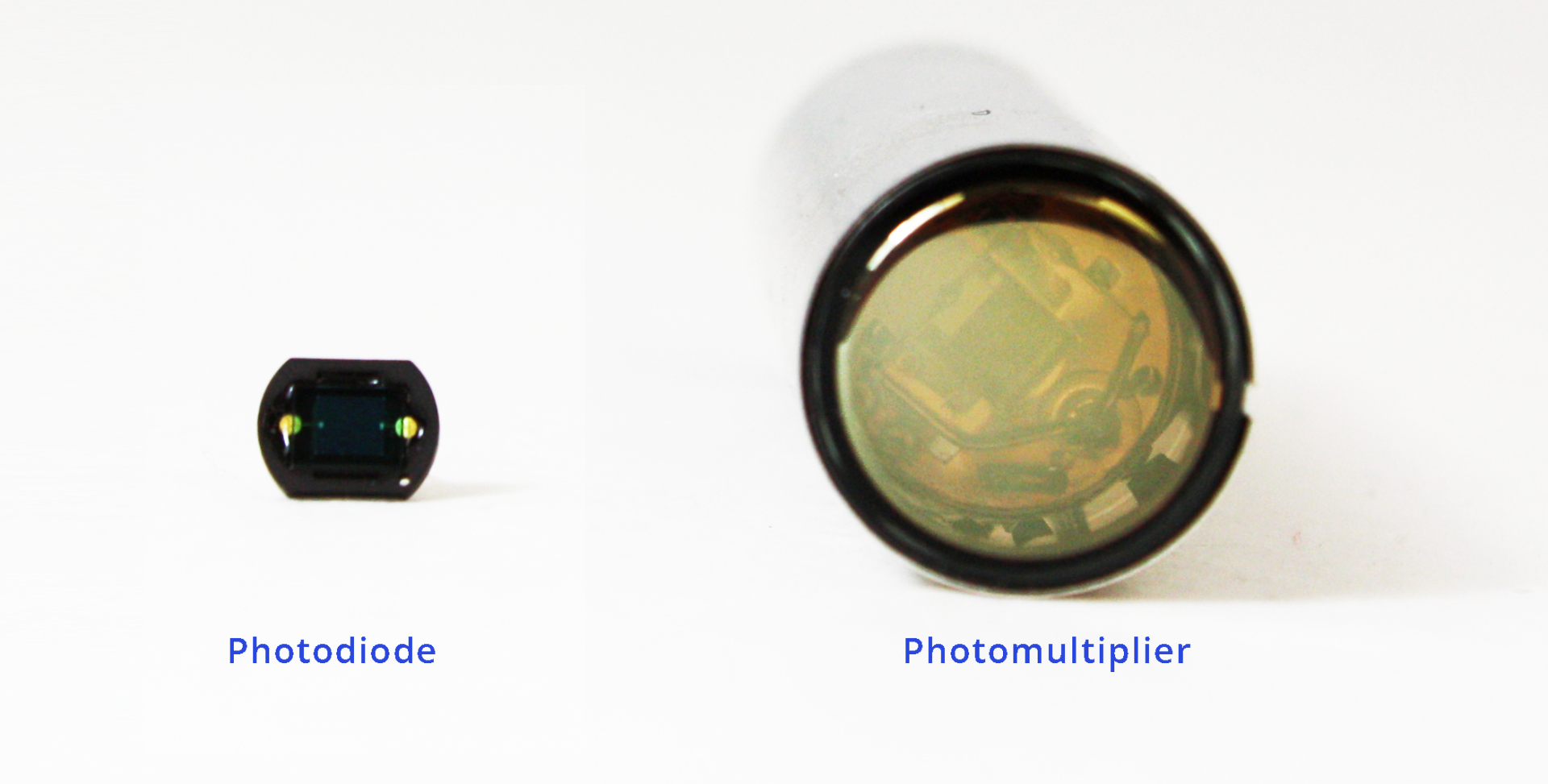

Use these ATP swab kits with the novaLUM II-X system, a luminometer that uses a photomultiplier tube to provide more accurate RLU detection than other sensors. This luminometer provides easy swab insertion and many features to support your quality management system (QMS). The system’s touchscreen offers a user-friendly interface, and the battery has a 9-hour run time.

With novaLUM II-X, you gain access to valuable analytics related to pass/fail rates, all while maintaining protective measures for data security. The novaLUM II-X system directly communicates with eBacMap Data Mapping & Trending Software to simply your tracking and trending. Data mapping, scheduling, and CAPA are all in a simple-to-understand application.

Apply data from the novaLUM II-X system to create customizable reports based on your organization’s needs. Program the system based on the swab site, facility layout, shift periods, and more. With a factory default of 0, you can get the most accurate reading possible and set a high standard for cleanliness.

Trust Charm Sciences for ATP Testing Kits

At Charm Sciences, our ATP swab kits and luminometers offer speed, simplicity, and sensitivity to verify cleaning processes. Our luminometer uses a photomultiplier tube to provide more accurate RLU detection than other sensors. The biofilm-breaking agent on our swabs has a unique characteristic that is unlike other products on the market to give you the most accurate reading possible. And our eBacMap Data Mapping & Trending software is an innovative way to view our data trends with trend rings, time-lapse video, and 3D 360 view.

Beyond ATP testing, we support testing for microbial detection, allergens, mycotoxins, antibiotics, and more. To learn more about Charm Sciences and our products, contact us today.

About Charm Sciences

Established in 1978 in Greater Boston, Charm Sciences helps protect consumers, manufacturers, and global brands from a variety of issues through the development of food safety, water quality, and environmental diagnostics tests and equipment. Selling directly and through its network of distributors, Charm’s products serve the dairy, feed and grain, food and beverage, water, healthcare, environmental, and industrial markets in more than 100 countries around the globe.